On 23 June this year, the opening meeting of the research and development consortium of a total of seven entities from Poland, Austria, Turkey and Portugal established under the EUREKA Initiative took place.

The aim of the project is to develop the technology of green hydrogen produced by electrolysis, with the electricity required to run the process coming from renewable energy sources (PV panels). The objective of the project will be accomplished by means of a pilot plant for the production of green ammonia (Harber Bosch synthesis method), which will be set up as part of the international project at the headquarters of the foreign consortium member, while the Polish contractors will be responsible to develop simulations of this process.

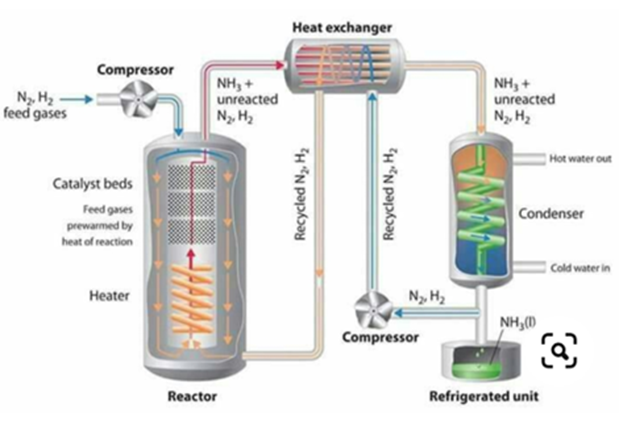

Haber-Bosch ammonia synthesis flowchart

Reducing the amount of carbon dioxide produced during the ammonia production process is key to achieving net zero emissions targets by 2050. The best way to reduce carbon dioxide emissions during ammonia production is to use low-carbon hydrogen. Therefore, green ammonia has attracted more attention in recent years. In this project, green ammonia will be produced in Turkey for decarbonisation applications and for data collection/comparison via a smart control system.

Turkish consortium partner SOCAR will use solar panels as a renewable energy source to power electrolysers. Green ammonia will be obtained using green hydrogen replacing fossil fuels. Austrian consortium BEIA will calculate the carbon footprint of all systems and this data will be added to the platform, which will be made by Erre Tech. A carbon certificate will be issued by BEIA. FUDA, a Hungarian partner, will prepare a socio-economic assessment of the entire supply chain in a green ammonia/hydrogen plant. Moreover, it will prepare guidelines for the creation of a hydrogen valley in Turkey as part of the EU plan to create new hydrogen valleys mainly in Central Europe. On the other hand, TMBK and Łukasiewicz – IEL will add value to the project by developing simulations of the planned ammonia plant and hydrogen production.

The simulation will provide important data that will enable us to compare the simulated system with the real one, as well as to compare some critical parameters. Moreover, the partners will develop an understanding of the needs and capabilities of other industries at the end of the project. The experience gained from the project will help partners to expand their market reach and develop new applications related to their business.

From the point of view of the national members of the international consortium, the most important practical aspect is the participation and execution of a complex project dealing with one of the most important problems of modern energy technology. The knowledge gained from the overall project will significantly enhance national competence in the areas of water electrolysis, hydrogen production, green ammonia plant management and the green hydrogen utilisation chain. The proposed approach to simulating the varying operating conditions of a green ammonia plant received high marks from the other consortium members and was a key argument for the Polish partners to join the international consortium.