Laboratory

Laboratory of Electrical Power Apparatus Testing (LAE)

The laboratory has 60 years of experience in type and design testing of medium- and high-voltage AC power equipment, as well as in type and design testing of switching and distribution apparatus up to 1000 V AC and up to 1500 V DC, and in testing DC traction devices, fuses, and switchboards with voltages up to 3000 V.

about us

Basic laboratory equipment:

- Three-phase short-circuit generator: rated power 100 MVA, short-circuit power 2500 MVA, rated voltage 10/12kV, frequency 50 Hz;

- Three-phase short-circuit generator: rated power 25 MVA, short-circuit power 500 MVA (3 s), rated voltage 10/12 kV, frequency 50 Hz;

- Three-phase power grid: 6 kV; 50 Hz, 110/6kV power transformer, 10 MVA;

- Single-phase short-circuit transformers: rated power 3 × 33.3 MVA, short-circuit power 3 × 750 MVA (2 s), primary voltage 10 kV, secondary voltages 15/30/60/110kV;

- High-current single-phase transformers with rated continuous power 3 × 10 MVA, symmetrical short-circuit power 41 MVA, primary voltage 10 kV, secondary voltage 250/500/1000 V, maximum short-circuit current 3s 120 kA, surge current 410 kA;

- High-voltage test generator with truncation system capable of generating 1.2/50 μs surges with 1200 kV amplitude and 8/20 μs switching shocks with 900 kV amplitude, maximum generator energy 120 kJ;

- 50 Hz test transformers with voltages: 300 kV, 120 kV, 80 kV, 30 kV;

- RL RC systems for the control of power supply parameters, TRV, and modelling (simulation) of load systems.

- three-phase short-circuit generator 12.5 MVA, 12 kV

- MIG 3603 C, 36 kV surge voltage generator,

- surge voltage test bench up to 150 kV

- DC short-circuit test bench up to 40 kA

- voltage tester up to 5 kV, 50 Hz

- four rectifier units rated for 3,000 V, 2,100 A each, short-circuit current up to 40 kA

- DC test rectifier up to 10,000 A

- climate chambers:

– Feutron climate chamber TPK1700(3921/02): temperature range 20°C to 90°C, humidity 10 to 95%

– Feutron 3836/15 chamber from -70°C to +180°C

– Feutron TSPK200 chamber capacity 2 × 200 dcm3 – temperature range from -70°C to + 180°C and from 10°C to 180°C

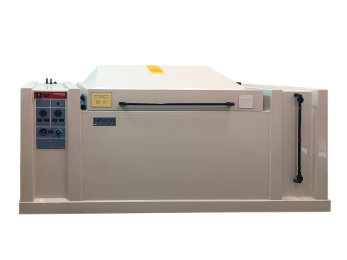

– salt mist spray chamber with a volume of 1.0 m3; temperature 20 to 60°C

- Weiss dust chamber for testing IP5X, IP6X protection rating, capacity 2.5 m3

- test bench for testing the durability of switchgear fixtures (lifting and transport) – loads up to 5,000 kg

The laboratories are equipped with a variety of instruments, devices, and low- and high-voltage measuring and recording equipment, including shunts, voltage dividers, current and voltage transformers, analog and digital instruments, RLC bridges, oscilloscopes, specialized transient and impulse waveform recorders, multi-channel temperature recorders, and optoelectronic systems for transmitting measurement data.

Tests performed

The Laboratory for Testing of Power Equipment conducts tests, measurements, and verification of functional characteristics and properties of high-voltage AC switchgear and controlgear, as well as compliance assessment of these products with the relevant standards in the scope of type tests and special tests. It also performs measurements, verification of functional characteristics, and assessment of the properties of low-voltage AC and DC switchgear and controlgear, as well as traction equipment, verifying their compliance with the relevant standards in the scope of type tests and special tests. Additionally, the laboratory carries out environmental testing and determination of IP and IK protection ratings across the full range.

The LAE Laboratory routinely performs the following tests:

- insulation testing with DC, AC and surge voltages in dry and rain conditions

- testing dielectric properties

- check of temperature increase

- checking the making capacity of the equipment with regard to rated, switching, critical and short-circuit and overload current

- short-time strength and n-second current tests

- dynamic strength test with peak current

- testing the effectiveness and short-circuit strength of protective circuits

- testing the internal arc resistance

- testing the time-current characteristics

- testing the operation of triggers and relays

- testing of fuses with lower and upper test current

- environmental tests at various exposures

- testing protection rating provided by enclosures (up to IP68)

- mechanical impact test (up to IK10)

- check of mechanical durability

- check of air and surface insulation gaps

- geometric measurements

- corrosion resistance in salt spray atmosphere

- testing resistance to incresed temperature (ball pressure)

- corrosion resistance in salt spray atmosphere

Contact

Testing Centre Director, Area Leader

mgr inż. Andrzej Kober