TECHNOLOGIES

3D Printing

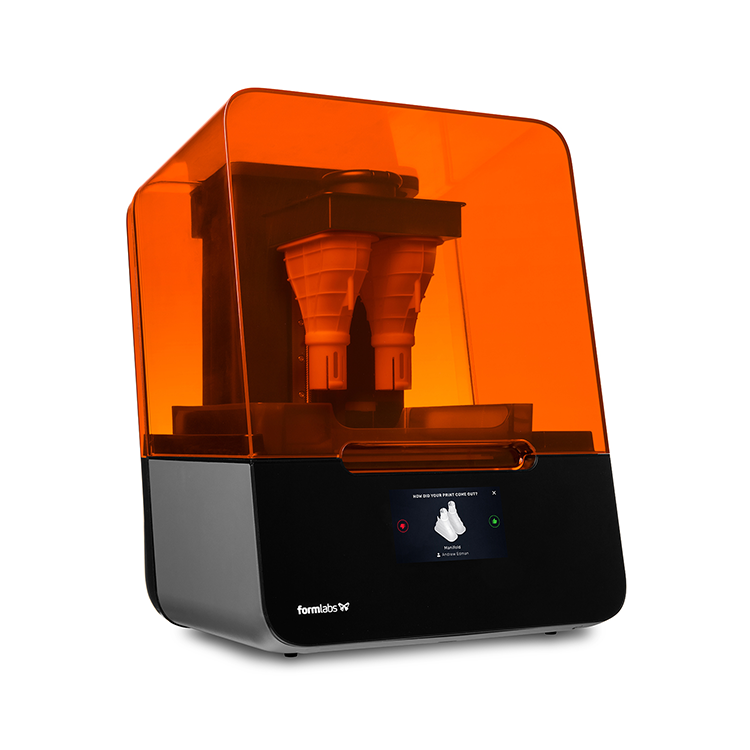

Formlabs Form 3

The printer works with Low Force Stereolithography technology, which is a variation of the well-known SLA technology. Photopolymer resins are cured using light, except that in the case of LFS, successive layers are cured in a flexible dish using a laser beam, resulting in very precise prints with a high-quality surface.

In addition to standard resin, which is most commonly used for prototyping, there are higher strength resins, rubber-like resins with rubber-like properties or dental resins that are biocompatible. The Form 3 model has a working area of 145 × 145 × 185 mm and can print layers of 25 – 300 µm.

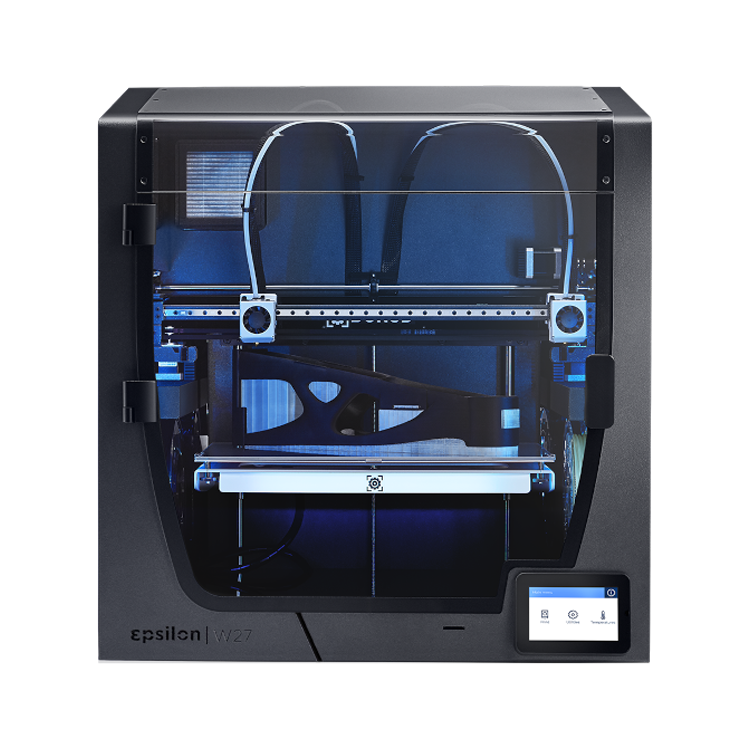

BCN3D Epsilon W27

Fused Deposition Modelling is the most widespread 3D printing technology, which is based on the use of thermoplastic filaments that are melted in an extruder and applied to the printed model in thin layers. The W27 printer is equipped with the IDEX system in the form of two independent extruders, allowing prints to be created simultaneously from two different materials or colours. Plastics such as ABS, PLA, PET-G, etc. can be used for printing. The available working area is 420 × 300 × 220 mm and the layer thickness is 50 – 500 µm.

Sinterlit Lisa Pro

In Selective Laser Sinterling technology, a 3D print is created by sintering a powdered thermoplastic polymer with a laser beam. Successive layers of powder are applied on top of each other and bonded at appropriate points. This technology offers the greatest freedom in the shaping of components while maintaining good mechanical properties and high accuracy. Polyamide, nylon, PEEK and others are used as the material. The Lisa Pro printer has a working area of 150 × 200 × 260 mm and the printed material can be layered in thicknesses of 75 – 175 µm.

Delta WASP 2040 Clay

The device is a variant of the WASP series of FDM printers that allows the creation of space prints from dense, semi-liquid materials. It allows objects to be created from materials such as porcelain, stoneware or clay. The working area is 200 mm in diameter and 400 mm high, with a minimum layer thickness of 500 µm.