Laboratory

Low Voltage equipment testing laboratory (LAN)

The laboratory has more than 60 years of experience in type testing and design testing of switchgear and distribution equipment up to 1,000 V AC and up to 1,500 V DC, as well as DC traction equipment, fuses and switchgear up to 3,000 V.

The Low Voltage equipment Testing Laboratory performs tests, measurements and verification of functional characteristics and verification of the properties of low-voltage AC, DC switchgear and traction equipment and verification of the conformity of these products with the requirements of the relevant standards in the field of type tests and special tests, as well as environmental tests and IP, IK protection rating, to the full extent.

about us

Basic laboratory equipment:

- three-phase short-circuit generator 12.5 MVA, 12 kV

- MIG 3603 C, 36 kV surge voltage generator,

- surge voltage test bench up to 150 kV

- DC short-circuit test bench up to 40 kA

- voltage tester up to 5 kV, 50 Hz

- four rectifier units rated for 3,000 V, 2,100 A each, short-circuit current up to 40 kA

- DC test rectifier up to 10,000 A

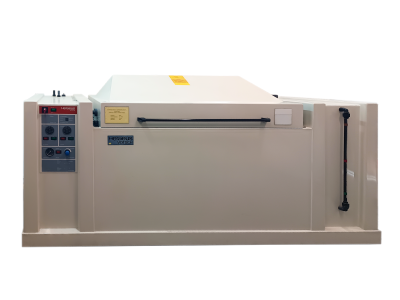

- climate chambers:

– Feutron climate chamber TPK1700(3921/02): temperature range 20°C to 90°C, humidity 10 to 95%

– Feutron 3836/15 chamber from -70°C to +180°C

– Feutron TSPK200 chamber capacity 2x 200 dcm3 – – temperature range from -70 oC +180 oC i od 10 oC do 180oC

– salt mist spray chamber with a volume of 1.0 m3; temperature 20 to 60°C

- Weiss dust chamber for testing IP5X, IP6X protection rating, capacity 2,5 m3

- test bench for testing the durability of switchgear fixtures (lifting and transport) – loads up to 5,000 kg

The range of products tested:

- AC circuit breakers

- contactors and motor starters

- disconnectors and switch-disconnectors, isolating switches and fused switch disconnectors

- switchgear and controlgear – indoor and outdoor units

- busbars

- distribution and control boards

- switchgear and units intended for installation on construction sites

- current transformers

- voltage transformers

- surge arresters

- capacitor units for power factor correction

- AC and DC fuses

- industrial fuses

- standard fuses

- connection fittings and clamps for copper wires

- threaded fuses

- circuit breakers for home systems

- circuit breakers for the protection of electrical equipment

- RCDs without integral overcurrent protection

- RCDs with integrated overcurrent protection

- electromechanical contactors for household use

- LV capacitor units for power factor correction

- connecting fittings for copper and aluminium cables and wires

- terminal blocks for copper wires

Tests performed

The LAN laboratory performs the following tests on daily basis:

- insulation testing with DC, AC and surge voltages in dry and rain conditions

- testing dielectric properties

- check of temperature increase

- checking the making capacity of the equipment with regard to rated, switching, critical and short-circuit and overload current

- short-time strength and n-second current tests

- dynamic strength test with peak current

- testing the effectiveness and short-circuit strength of protective circuits

- testing the internal arc resistance

- testing the time-current characteristics

- testing the operation of triggers and relays

- testing of fuses with lower and upper test current

- environmental tests at various exposures

- testing protection rating provided by enclosures (up to IP68)

- mechanical impact test (up to IK10)

- testing the mechanical strength of enclosures

- check of mechanical durability

- testing resistance to incresed temperature (ball pressure)

- check of air and surface insulation gaps

- geometric measurements

- corrosion resistance in salt spray atmosphere

Testing capabilities LAN - AB 074

Alternating current (AC)

Short-circuit current (3 phase) rms

max.120 kA

Short-circuit current (1 phase) rms

max 210 kA

Short-circuit current peak

max 400 kA

Arc protection test

max 63 kA 0.5s. 50 kA 1 s

Switching tests

max. 1 = 50 k A – 7.2 kV

40 kA -12 kV

31.5 kA – 17.5 kV

20kA – 24 kV

8 k A – 36 kV

Temperature rise

max 12 kA

Direct current (DC)

Short-circuit current

max 40 kA

Switching tests

max 80 kA for 1 kV

max 50 kA for 4 kV

Temperature rise

max 10 kA

Voltage tests

Mains frequency voltage

max 300 kV. 50 Hz

Lightning surge voltage 1.2/50

max 1200 kV. 120 kJ

Switching surge voltage 8/20

max 900 kV, 120 kJ

Climate chamber tests (próby A, B, Cab, Db)

Temperature range

-70oC -180 oC

Humidity range

10% – 95% RH

IP tests

up to lP68

IK tests

Do lK1O

Laboratory

Contact

Testing Centre Director, Area Leader

mgr inż. Andrzej Kober