Laboratory

Testing Laboratory for Electrotechnical Materials [LME]

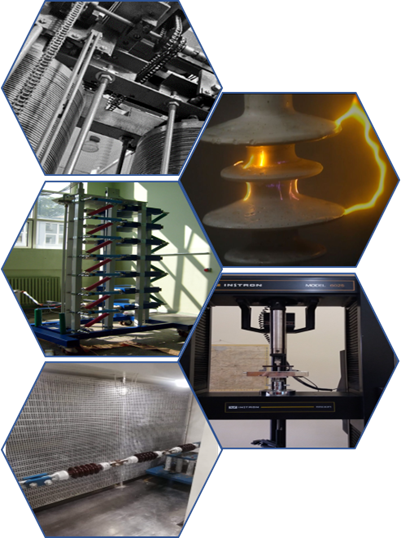

The Testing Laboratory has more than 20 years’ experience in the testing of electrotechnical materials in the following areas: physicochemical, electrical, mechanical and thermal properties, flame propagation resistance, insolation resistance, environmental resistance, electrical power testing of protective equipment, testing of ceramic and glass insulators, testing of composite, polymer and organic plastic insulators above 1kV.

About us

The Testing Laboratory for Electrotechnical Materials holds the AB 067 certificate from the Polish Centre for Accreditation, ensuring competence, reliability and independence. Tests are carried out in accordance with the scope and methods given in current Polish and international standards (PN, EN, ISO, ASTM).

The Testing Laboratory for Electrotechnical Materials focuses on the electrical, mechanical, physicochemical properties (including density, porosity, coefficient of linear expansion, resistance to sudden temperature changes) of electrotechnical materials and products, electrical insulators (ceramic and composite) and ceramic masses and glass. It also performs fire resistance tests on electrotechnical materials and products and electrical and mechanical tests on personal protective equipment, plastic and rubber products.

The Testing Laboratory for Electrotechnical Materials also performs unique tests under extreme environmental conditions. A salt spray chamber is used for this purpose, as is the thermo-mechanical test chamber.

Moreover, it carries out expert work, offers technical advice and provides technology services.

An advantage offered by the Testing Laboratory is that the same property can be measured for the material and the product made from it, e.g. mechanical and electrical strength performed on standardised material samples (beams and discs) and on insulators of various types. This is complemented by ageing tests taking into account the most important environmental factors – moisture, temperature, corrosive environments (salt spray and SO2), ultraviolet radiation.

The Testing Laboratory employs competent staff in all positions and ensures proper supervision of all staff and the tests performed. The laboratory has calibrated and tested equipment that enables accurate measurements to be made.

The full range of tests can be found in the scope of accreditation of the Testing Laboratory for Electrotechnical Materials no. AB 067.

Tests performed

The AB067 Testing Laboratory for Electrotechnical Materials carries out work in the areas of:

- Low-, medium- and high-voltage insulators – both ceramic (including traction) and composite, polymeric and organic materials, non-directional surge arresters

- Materials testing: ceramic masses, glass materials, plastics as well as electro-insulating products

- Testing of electrical, electronic and telecommunications equipment

- Testing of cables and wires, including materials for cable insulation and sheaths

- Tests on the vertical flame spread of insulated cables, electric cables, optical fibre cables and heating cables and tests on the flammability category of solid electrical insulating materials

- Protective equipment – protective equipment for periodic as well as full tests

The Testing Laboratory for Electrotechnical Materials has unique chambers for testing under extreme environmental conditions, including a salt spray chamber and a thermo-mechanical test chamber. It has, among other things:

- HAEFELY pulse voltage generator

Pulse voltage generator with CS 700-500 divider and HiAS 743 recording system, 700 kV, 35 kJ - High-voltage test bench, 50 Hz

High-voltage test bench including rain test chamber - Salt spray chamber

Certified chamber for creep discharge and erosion resistance testing - Thermo-mechanical chamber

Max. tensile force 300 kN, Max. bending force 50 kN

Chamber dimensions: 2500/1000/1500 mm

Max. temp. + 55°C

Min, temp. – 45°C - Instron testing machine Model 6025

Max. bending and tensile force 100 kN

Max. bending force 10 kN - Louis Schopper strength testing machine

Max. tensile strength 300 kN

Max. bending strength 25 kN

Max. compression strength 25 kN

Scope of tests:

- testing of cables and winding wires

- testing the mechanical properties of metals

- testing the electrical properties of electrical insulating materials

- electrical strength testing of electrotechnical products (coatings and insulation)

- resistance testing of electrotechnical products

- testing flammability of plastics

- testing flammability of electrical insulating materials

- testing flammability of electrical insulating materials

- testing of flammability categories of electrical insulating materials

- testing resistance to environment – climatic tests

- insolation resistance test

- testing of protective electrical insulation equipment

- testing the properties of ceramic and glass materials

- testing of composite insulators

- testing of polymeric insulators

- testing of ceramic insulators for overhead lines

- testing of low-voltage ceramic insulators

- testing of non-directional surge arresters