FOR BUSINESS

Laboratory

We offer our current and future customers a very high level of service, performed by a qualified team of people with many years of experience in laboratory work. We provide a reliable and professional service and discounts for regular customers.

ACRETTED:

UNACCREDITED:

For business

Research centers

Testing Centre for Energy Conversion and Storage (CPM):

- Power Supply and Energy Conversion Systems Research Team – GPE

- Smart Infrastructure Technologies (Smart Grid) Research Group – GTI

- Testing Laboratory for Energy Conversion and Storage - LPM

Testing Centre for Electromobility and Intelligent Transport (CET):

- Integrated Intelligent Transport Systems Research Group - GST

- Electric Transport Infrastructure Research Group – GIT

- Electrical Drives and Controls Research Group – GNE

- Testing Laboratory for Electromobility and Intelligent Transport - LET

Testing Centre for Electrical Power Equipment and Equipment (CAE)

- Power Instrumentation and Systems Research Group - GSE

- Electrical Equipment Testing Laboratory (LUE)

- Laboratory of Electrical Power Apparatus Testing (LAE)

- Calibration Laboratory (LBW)

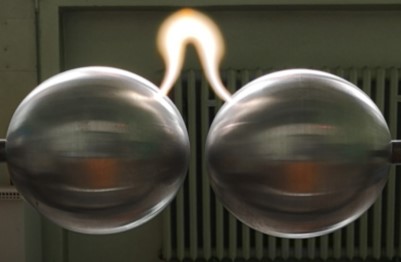

Research Center for Hydrogen Technology (CTW):

- Hydrogen Storage Technology Research Group - GMW

- Hydrogen Generation and Processing Research Group – GPW

- Hydrogen Technology and Catalysis Laboratory – LTW

Testing Centre for Electrotechnical Materials (CME)

- Composite Materials and Recycling Research Group – GMR

- New Materials for Hydrogen Technologies Research Group - GMT

- New Materials for Energy Generation and Storage Technologies Research Group - GWM

- Materials Manufacturing Technology Research Group – GTW

- Testing Laboratory for Electrotechnical Materials - LME

FOR BUSINESS

PRODUCTS

Composite line traction and buckled insulators

very good hydrophobic properties/no need to clean the insulators, UV and ozone resistance – reduced operating cost/

The materials used for production are recognised and confirmed by the necessary tests and certificates.

Production process based on modern production and quality management systems.

Our Customers

FUK Kościan, PKP PLK SA, Powerlines Products Germany

Electrical Insulating Sleeves

Sheaths are distinguished by high resistance to damage during assembly/any technology bending

The production process is based on modern production and quality management systems.

The materials used for production are recognised raw materials, proven by the necessary tests and certificates.

Our Customers:

Tamel Tarnów, Cantoni Celma Indukta, Lincoln Bester, Sigma Elektro, Room RYN, Damel

Composite support insulators

Very good hydrophobic properties/no need to clean the insulators, UV and ozone resistance – reduced operating and installation cost – low weight of the insulators compared to porcelain/

The materials used are recognised and certified raw materials.

Production process based on modern production and quality management systems.

Our Customers:

ZPUE Włoszczowa, ALPAR Kozienice, FUK, Richard Switzerland

Composite hollow insulators

Very good hydrophobic properties/no need to clean insulators, UV and ozone resistance – reduced operating and installation cost – low weight of insulators compared to porcelain, use in seismic regions – fewer failures.

The silicone used ensures trouble-free operation of the insulators. As part of the Łukasiewicz – IEL Research Network, we have access to the latest developments in electrical engineering technology and materials science.

The materials used for production are recognised raw materials, proven by the necessary tests and certificates.

Our Customers:

Siemens Germany, Tridelta Germany, Pfisterer Germany, Vanguard USA, Ritz Messwandler Germany

Glass-epoxy tubes for general technical purposes

Wide dimensional range, high quality combined with moderate pricing.

Production process based on modern production and quality management systems.

The materials used for production are recognised raw materials, proven by the necessary tests and certificates.

Our Customers:

Activation Krakow, Hubix

Rail static converter

30 rail converters have been designed, manufactured and installed, ensuring reliability and increasing flexibility in configuring the inverter-compressor system on the EP 09 series locomotives produced by Pafawag Wrocław.

Through pneumatic systems, the current collector is raised and held, doors are opened and closed in the carriages, toilets are operated, sand is ejected from locomotive sandboxes by means of compressed air, allowing the heavy train to move on tracks that are icy in winter or otherwise slippery.

Our Customers:

PKP InterCity

Heating cables

The cables are very versatile heating elements due to their wide heating temperature range, high flexibility and light weight. The heating cables can be arranged in the form of lamellas with a large bending radius, coils and strands, as well as being formed into flexible heating mats or encapsulated into rigid panels.

Flexible heating cables can operate at DC or AC voltages not exceeding 500 V. It is possible to use them in conditions of increased humidity, even up to 95%.

Our Customers:

ENERGO, Lamare, LCM Schokoladenmaschinen GmbH

Composite shafts for general engineering purposes

The products, which are made using state-of-the-art programmed winding technology, are distinguished by low mass, low mass moment of inertia and high resistance to mechanical loads.

Production process based on modern production and quality management systems.

Our Customers:

Inometa GmbH Germany

FOR BUSINESS

Patents

List of patents and protection rights held by Łukasiewicz – IEL

PAT.225715 – Discrete structure transformer, particularly rotary, Artur Jan Moradewicz, Rafał Miskiewicz

PAT.227934 – Electricity conversion system using matrix converters connected in parallel, Ryszard Strzelecki, Tomasz Sak, Natalia Strzelecka

PAT.228547 – Method and system for power conversion using multilevel inverters connected in parallel, Ryszard Strzelecki, Tomasz Sak, Natalia Strzelecka

PAT.235485 – Method of producing anticorrosive pigment, anticorrosive pigment and its application, Wojciech Szymański, Agnieszka Halama, Grzegorz Paściak

PAT.238059 – Method of trapping ferromagnetic oscillating particles inside a flow-through chemical or physical reactor, Wojciech Lipiec

R.193076 – IEL + wordmark

Certification

Irrespective of the laboratory tests conducted, the Łukasiewicz Research Network – Institute of Electrical Engineering has an Electrotechnical Products Certification Department within its structures. The department’s employees provide customers and users of products with reliable, impartial, independent and complete certification of the conformity of products with the requirements of the applicable subject standards.

The Łukasiewicz Research Network – Institute of Electrical Engineering is authorised to issue certificates for compliance with norms/normative documents. The certification is based on PN-EN ISO/IEC 17065:2013-03 – Conformity assessment requirements for bodies certifying products, processes and services.

The Product Certification Body – Łukasiewicz Research Network – Institute of Electrical Engineering in Warsaw is accredited by the Polish Centre for Accreditation no. AC 168, with an accreditation cycle from 03.09.2024 to 23.09.2028.

DOCUMENTS TO DOWNLOAD:

- Scope of accreditation AC 168

- Accreditation Certificate AC168

- Scope of certification

- Quality policy

- Declaration of impartiality and independence

- Certification programme for electrotechnical products type 1a

- Application form for certification

- Annex to the application form - list of parameters

- Complaints and appeals - Customer information guide

Achievements

See the projects we have completed